Product

Car Seat Cover Cutting Machine

Different tool options:

- Vibrating knife cutting.

- Pneumatic knife for multi-layer cutting.

- CNC cutting machine is suitable for cutting car interior materials such as car floor mats, car seat covers, and car films.

- With stable computer control performance, fixed working table, and manual auxiliary feeding.

- It does not require special professional knowledge.

- It can complete the entire cutting process after simple training.

Product Parameter

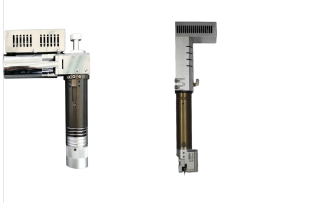

Product Cutting Head

Product Feature

1.The effective cutting area of the machine is 2500mm * 1600mm, and the efficient cutting speed can replace manual cutting by 2-3 people.

2.And it can increase the material utilization rate by 10%.

Product Cut Sample