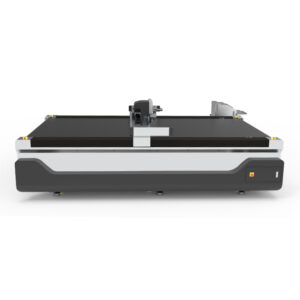

Composite Materials Cutting Machine

YUCHEN is a forward-thinking manufacturing company that specializes in the research and development, production, sales, and service of cutting-edge equipment for flexible material cutting. With a decade of experience since 2010, we have established ourselves as a reputed factory and supplier of Artificial Turf Cutting Machine in China. Additionally, we proudly export a wide range of CNC equipment, including artificial turf cutting machines, fiberglass cutting machines, pvc tarpaulin cutting machines, and polyester fiber acoustic board cutting machines, among others.

YUCHEN Also Produces Cutting Machines For Composite Materials

A Carbon Fiber Prepreg Cutting Machine is a specialized piece of equipment designed to precisely cut and shape composite materials. Moreover, composite materials are made by combining two or more materials with different properties to create a material with enhanced characteristics.

Benefits of Composite Materials Cutting Machines:

- Precision Cutting: These machines provide accurate and precise cutting of composite materials, minimizing material waste and ensuring product quality.

- Efficiency: Automated cutting processes increase production efficiency and reduce labor requirements. Normally, our machines adopt Panasonic servo motor Guide rail and rack.

- Safety Features: Equipped with safety features to protect operators from potential hazards during cutting operations.

- Energy Efficiency: Designed with energy-efficient components to minimize operating costs.

- Technical Support: Reputable manufacturers offer comprehensive technical support, including installation assistance, training, and after-sales service.

Types of Advantageous Composite Materials Cutting Machines From YUCHEN:

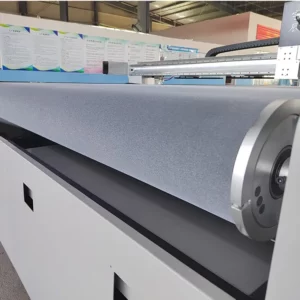

Artificial Turf Cutting Machine:

Specifically designed for cutting artificial turf, this machine ensures precise and clean cutting of turf rolls, meeting the requirements of sports fields, landscaping projects, and recreational areas.

Carbon Fiber Prepreg Cutting Machine:

Suitable for cutting carbon fiber prepreg, a composite material used in aerospace, automotive, and sports industries. It provides high-precision cutting to achieve complex shapes and patterns.

Fiberglass Cutting Machine:

Ideal for cutting fiberglass, a commonly used composite material in boat building, automotive parts, and wind turbine blades. This machine offers accurate cutting and minimizes material waste.

PVC Tarpaulin Cutting Machine:

Designed for cutting PVC tarpaulin, a versatile material used in construction, transportation, and outdoor applications. It ensures efficient cutting of large tarpaulin sheets.