Leather is a common flexible material in our daily life. Leather goods cover almost all aspects of our lives, leather bags, leather shoes, leather clothing, sofas, car seats…

With the continuous upgrading of personalized consumption, people are no longer satisfied with ordinary leather products.

First of all, we need to understand the process of cutting natural leather with a leather cutting machine as follows:

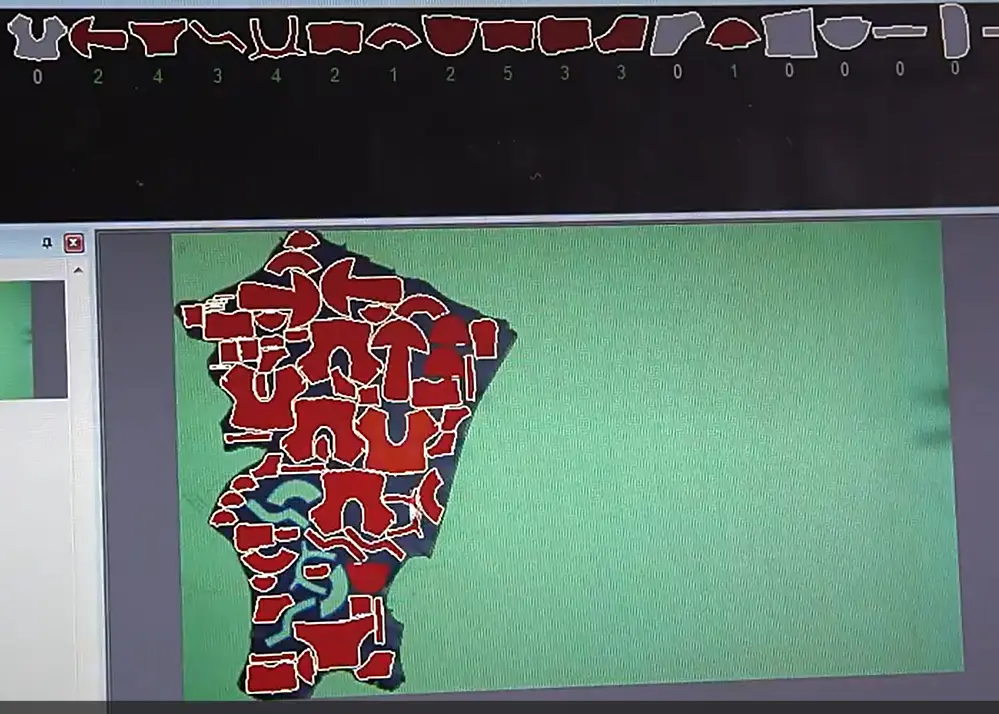

1: Since the edge contour of natural leather is irregular, a camera system needs to be added to identify defects on the leather and extract the leather contour.

2: After identifying and extracting the available contours (processing area), import the graphics to be cut and automatically layout them, and then cut.

3: After cutting, you can add a projector to project the cutting graphics onto the work surface to facilitate picking up materials.

Complementing our leather cutting machines, we also offer dedicated leather bag cutting machine, designed specifically for the efficient and precise fabrication of leather bags and accessories

Yuchen CNC cutting machine has two major advantages in cutting leather.

1: With the support of camera software, the leather utilization rate can reach 75%-80%.

2: The product quality and structural stability of the machine itself. 3: There are different solutions to deal with different work scenarios, whether it is a small fixed machine or a large automatic feeding machine. All have complete customer application cases and experience.